Wir sorgen dafür, dass Ihre

Produkte in Asien perfekt produziert und

genau nach Ihren Vorgaben bei Ihnen ankommen.

Mehr InfoWir haben das Wissen über die Chemie der Produkte.

Wir wissen was getestet werden muss -

denn nicht jeder Test ist sinnvoll und kostet nur Geld...

Mehr InformationenWir kennen beide Seiten.

Die asiatischen Hersteller und die Ansprüche

unserer europäischen Kunden.

Mehr InformationenWir kümmern uns für Sie um eine einwandfreie

und rechtlich sichere Dokumentation

Ihrer Produktion in Asien.

Mehr InfoSie produzieren bereits oder planen, in Asien

zu produzieren? Wir unterstützen Sie dabei.

Die LGT Logistic and Goods Testing Institute GmbH ist ein Anbieter maßgeschneiderter Dienstleistungen zur Qualitätssicherung von technisch anspruchsvollen Produkten aus Asien. Effizient, wirtschaftlich attraktiv und dem hohen deutschen Qualitätsverständnis entsprechend schließen wir die Lücke zwischen den Erwartungen des Marktes und den Fähigkeiten der Lieferanten.

Dabei agieren wir überwiegend direkt beim Hersteller vor Ort und befreien unsere Kunden von allen zeit- und kostenintensiven Arbeiten, die mit der Beschaffung in Asien verbunden sind.

Produkt-Inspektion

Inspektion Ihrer Produkte während des Herstellungsprozesses und kurz vor Versand.

- Mehr Info

Produkt-Prüfung

Test Ihrer Produkte auf Normerfüllung, Chemische Unbedenklichkeit (REACH) und Produktzuverlässigkeit.

- Mehr Info

Produzenten-Entwicklung

Entwicklung der verfügbaren Hersteller zu verlässlichen Sourcing-Partnern.

- Mehr Info

Dokumentation

Technische Dokumentation der vom Gesetzgeber geforderten Informationen.

- Mehr Info

Full Service für Ihre Produktion in Asien.

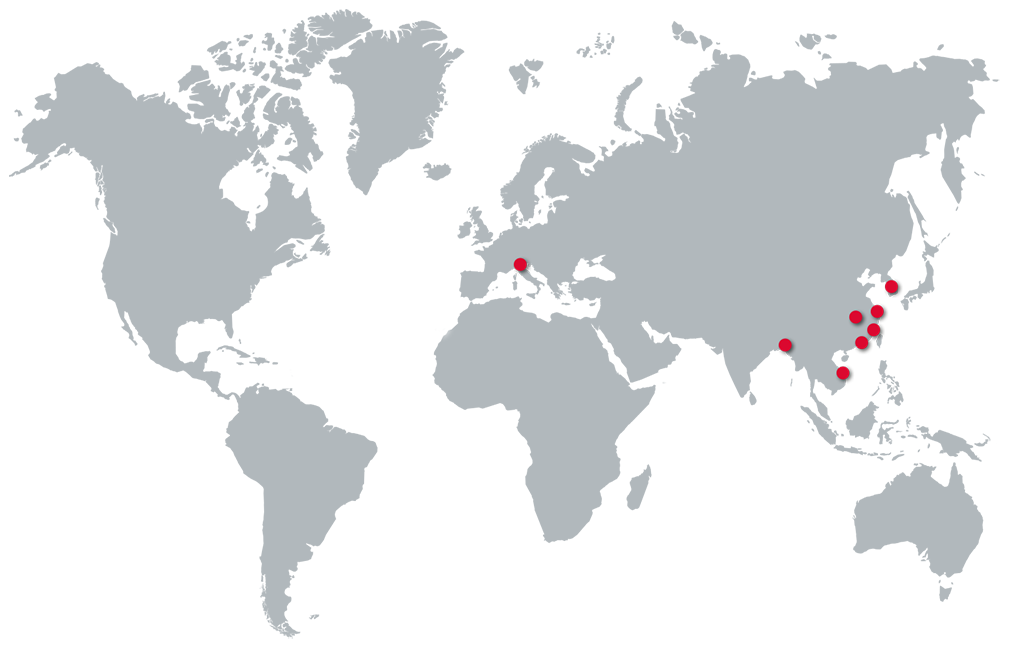

Wir sind für Sie vor Ort und an Ihrer Stelle.

Unsere Teams sind für Ihre Produktionen in den wichtigsten Ländern und Regionen wie z.B. Wenzhou, Shenzen, Xiamen, Yingtan, Korea, Bangladesh, Vietnam sowie in Italien verfügbar und kümmern sich um die Produktionsüberwachung und Einhaltung Ihrer Qualitätsvorgaben.

Unsere Service- und Beratungsleistungen für Ihre erfolgreiche Produktion in Asien

Vertrauen in Ihre asiatischen Produzenten ist gut.

Wir wissen aus Erfahrung - Kontrolle ist besser.

Produzenten in Asien gibt es viele und richtig günstige.

Wir kennen oder finden den genau Passenden.

EU-Normen sind kompliziert.

Wir kennen uns damit aus.

Der Gesetzgeber fordert.

Wir dokumentieren für Sie.